Overview: M/s Shreeji International, located in Jeoni Mandi, Agra, was a renowned export shoe manufacturing unit. On May 24, 2002, tragedy struck when a fire broke out at the factory premises, resulting in significant loss of life and property. This case study delves into the incident, its causes, response, and the lessons learned regarding fire safety in industrial settings.

Background: Agra, known globally for its historical monuments like the Taj Mahal, hosts numerous shoe manufacturing units due to its thriving export industry. These factories, including M/s Shreeji International, dealt with various hazards such as storage of flammable adhesives, bulk quantities of raw leather sheets, unfinished and finished shoes, and packaging materials.

Incident Details: The fire incident occurred due to negligent smoking during the transfer of flammable adhesive containers, leading to the ignition of flammable vapors and subsequent explosions. The lack of primary containment and firefighting equipment exacerbated the situation, causing the fire to spread rapidly. Compounding the issue was the locked exit gate, trapping around 60-70 employees in a back room with wire meshed windows, hindering their escape.Situated in one of the portion of Ist Floor of LIC building. Other commercial units situated in this LIC building

1.RCF Godown

2.M/s Usha International Factory

3.Khoda Shoes

4.Dainik Jagran Newpaper Press

5.M/s S M Export

6.M/s Jaipur Golden Transport

7.U P Rajya Bhandran Nigam Godown

A View of L. I. C. Building, AGRA

Deficiencies Noticed :

1 No. Staircase fitted with iron channel gate normally kept locked.

Other main staircase used for both entrance & exit.

Storage of 30-40 drums of each 20 lts. cap of highly flammable adhesive near entrance point of main staircase.

Approx. 300-350 employees working on incident day.

Distance of factory from nearest Fire Station – 7 km.

Except few unserviceable Fire Extinguishers, No other fire fighting equipment was available in the factory.

Side View of Shoe Factory, AGRA

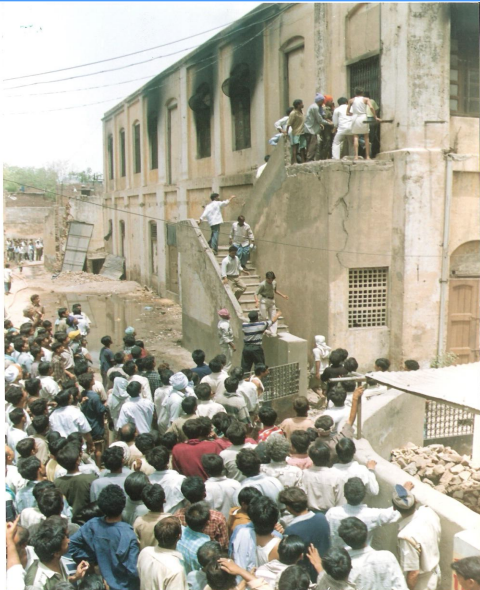

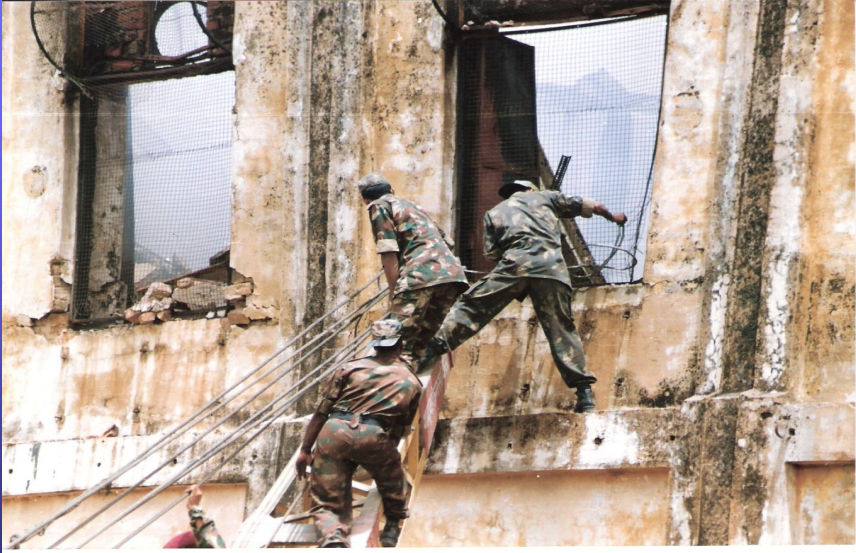

Response and Rescue Operation: The fire was reported to the Idgah fire station at 10:32 AM, with fire services arriving at the site by 10:45 AM. A massive rescue operation ensued, involving fire service units from various districts, the Air Force, COD, Army, and local authorities. Despite challenges like high flame intensity and ongoing explosions, around 250-300 employees were successfully rescued. However, due to the chaotic scene and structural barriers, several employees in the back room could not be saved immediately.

View of window fitted with wire mesh

Due to high flame intensity & ongoing explosions, all others trapped in back side portion could not be rescued.

Huge crowd gathered.

Created law & order problem.

Hampered rescue & fire fighting operation.

District Police force managed the crowd with great difficulty.

FIRE FIGHTING & RESCUE OPERATION: The fire resulted in around 39 casualties completely burnt brought down & shifted to hospital. Army & fire vehicles of Air Force, COD & nearby district returned to their respective units at 7.00 PM. Fire Service, Agra remained at site for searching operation of casualties and extinguishing the smouldering fire. Two more casualties were searched & shifted to hospital on 25, May 2002. On 26, May 2002. Hon’ble chief minister visited the site and appreciated the efforts made by local administration in handling the fire disaster.Fire and rescue operation continued up to 28, May 2002.Later on 3 casualties expired during treatment in hospital. The property damage was estimated at approximately Rs. 1.05 crores, while the total property at risk was valued at Rs. 8.83 crores. The tragic incident highlighted the critical importance of robust fire safety measures in industrial premises.

Lessons Learned and Recommendations: Following the incident, several recommendations were made to enhance fire safety measures in industrial units:

- Mandatory registration and renewal of factory licenses under relevant safety acts.

- Training programs for handling hazardous materials, firefighting equipment operation, and evacuation procedures.

- Empowering fire safety officers to enforce and maintain safety arrangements.

- Ensuring sufficient water storage and safe storage of flammable materials.

- Provision of multiple exit gates, regular equipment testing, and compliance with safety standards.

- Implementation of building codes and fire safety regulations as per national standards.

- Stringent penalties for non-compliance and strict adherence to safety protocols.

Conclusion: The Shreeji International Factory Fire Incident serves as a stark reminder of the devastating consequences of inadequate fire safety measures in industrial settings. It underscores the critical need for proactive safety protocols, training, and regulatory enforcement to prevent such tragedies and safeguard lives and property.